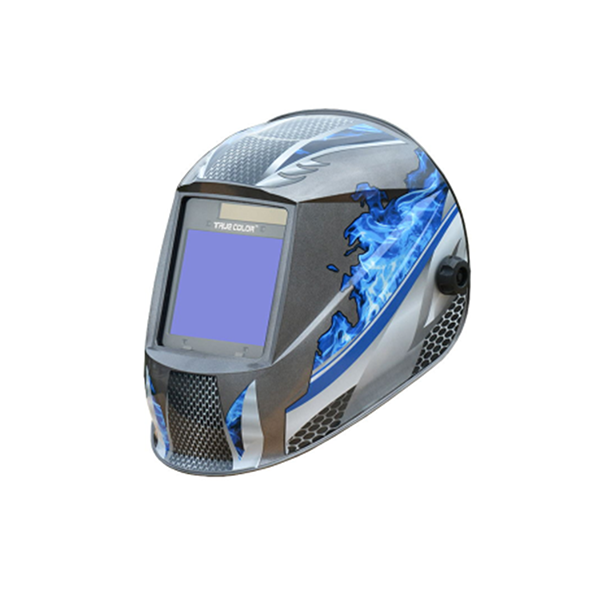

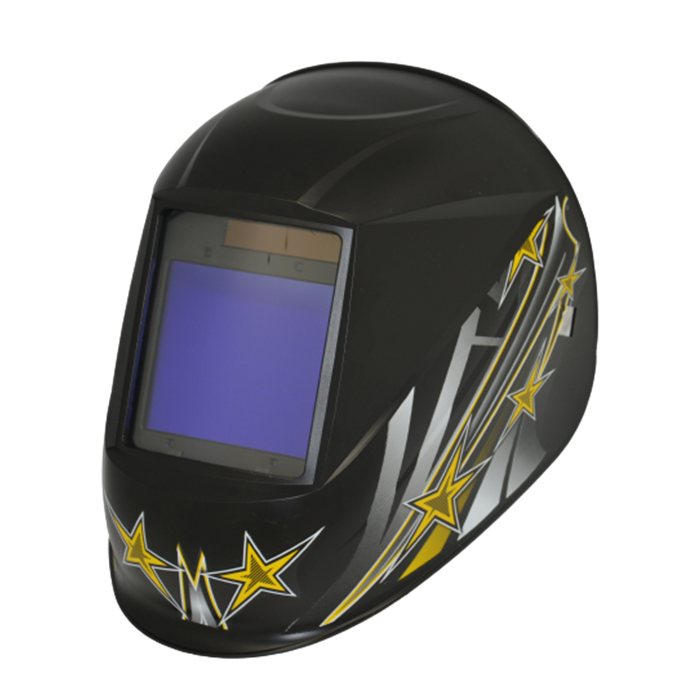

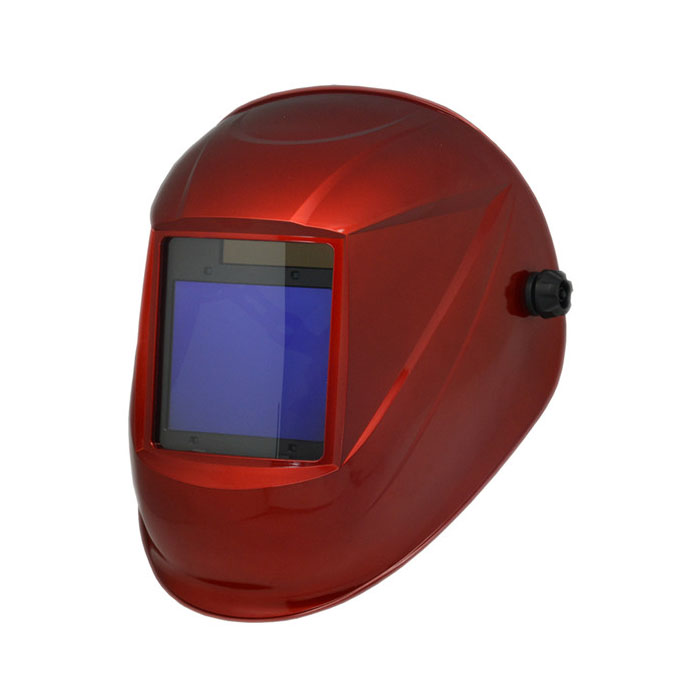

Helmete e kholo ea Lifensetere ea Solar Automatic Photowelding

Tlhaloso

Helmete ea "Auto Darkening Welding" e etselitsoe ho sireletsa mahlo a hau le sefahleho sa hau ho tsoa litlhaseng, spatter le mahlaseli a kotsi tlas'a maemo a tloaelehileng a ho cheselletsa. Sefe ea ho fifala ka boits'oaro e fetoha ho tloha boemong bo hlakileng ho ea boemong bo lefifi ha arc e otloa, 'me e khutlela boemong bo hlakileng ha welding e emisa.

Likaroloana

♦ Helmete ea setsebi ea ho cheselletsa

♦ Sehlopha sa Optical : 1/1/1/1 kapa 1/1/1/2

♦ Pono e kholo ea pono

♦ Welding & Grinding & Cutting

♦ Ka litekanyetso tsa CE, ANSI,CSA,AS/NZS

Lintlha tsa lihlahisoa

| MOKHOA | TN360-ADF9120 |

| Sehlopha sa Optical | 1/1/1/1 kapa 1/1/1/2 |

| Boemo ba sefe | 114 × 133 × 10 limilimithara |

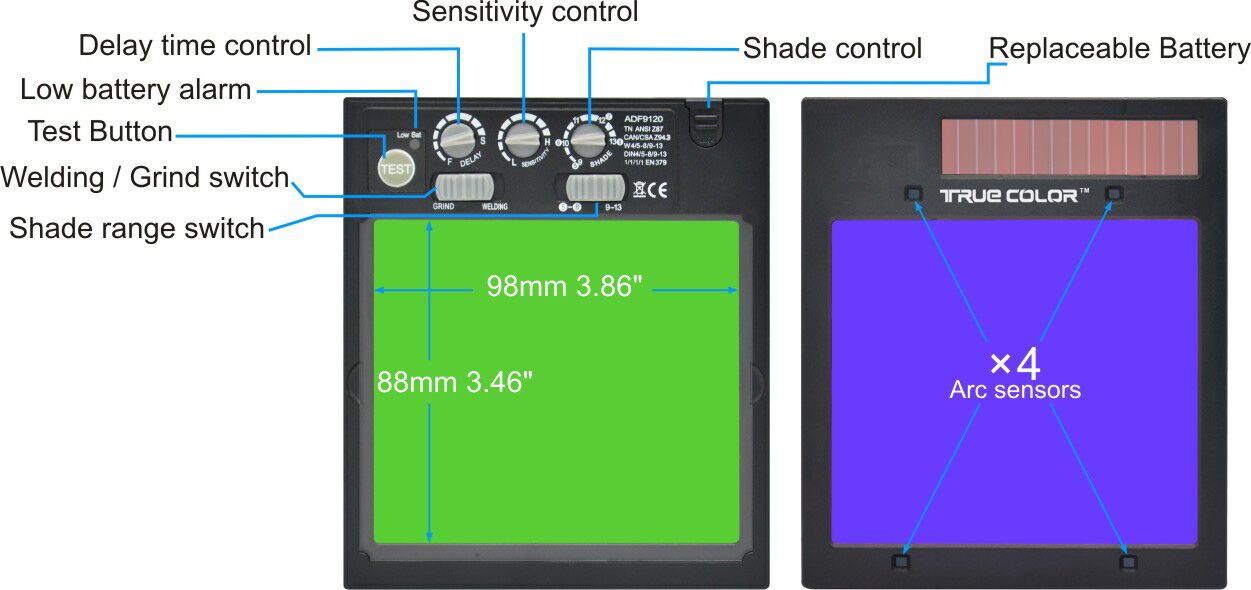

| Boholo ba pono | 98 × 88 limilimithara |

| Moriti oa boemo bo khanyang | #3 |

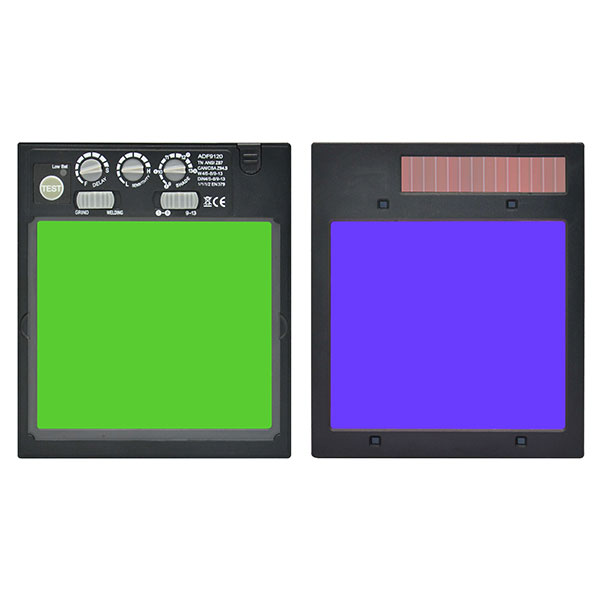

| Moriti wa boemo bo lefifi | Moriti o feto-fetohang DIN5-8/9-13, tlhophiso ea Knob ea ka hare |

| Ho fetola nako | 1/25000S ho tloha Leseling ho ea Lefifing |

| Nako ea ho hlaphoheloa ha Auto | 0.2 S-1.0S Ho potlakela ho ea butle, ho fetoha ha mohato |

| Taolo ea kutlo | Tlase ho ea holimo, Tokiso e se nang mohato |

| Sensor ea arc | 4 |

| Li-amps tsa TIG tse tlase li lekantsoe | AC/DC TIG,> 5 amps |

| MOSEBETSI OA HO HALA | Ee (#3) |

| Sekhahla sa moriti | Ho joalo (DIN5-8) |

| ADF Itlhahlobe | Ee |

| Batt e tlase | Ho joalo (LED e khubelu) |

| Tšireletso ea UV / IR | Ho fihla ho DIN16 ka linako tsohle |

| Phepelo ea motlakase | Lisele tsa Solar & Betri ea Lithium e ka nkeloang sebaka ( CR2450) |

| Matla a ho bulela/ tima | Ka ho feletseng |

| Lintho tse bonahalang | Lebelo le phahameng la tšusumetso, Nylon |

| Mocheso oa ho sebetsa | ho tloha -10 ℃–+55 ℃ |

| Mocheso oa ho boloka | ho tloha -20 ℃–+70 ℃ |

| Tiisetso | lilemo tse 2 |

| Standard | CE EN175 & EN379, ANSI Z87.1, CSA Z94.3 |

| Lethathamo la kopo | Stick Welding (SMAW); TIG DC∾ TIG Pulse DC; TIG Pulse AC; MIG/MAG/CO2; MIG/MAG Pulse; Plasma Arc Cutting (PAC); Plasma Arc Welding (PAW); Ho sila. |

1. Pele ho Welding

1.1 Netefatsa hore lifilimi tsa ts'ireletso tsa kahare le kantle li tlosoa lilenseng.

1.2 Sheba hore na libeteri li na le matla a lekaneng a ho sebelisa helmete. Cartridge ea filthara e ka tšoarella lihora tse 5,000 tsa ts'ebetso e tsamaisoang ke libeteri tsa lithium le lisele tsa letsatsi. Ha matla a betri a le tlase, letšoao la LED la Battery e Tlaase le tla khantša. Lense ea filthara ea khatriji e kanna ea se sebetse hantle. Fetola libeteri (sheba Phetoho ea Battery ea Tlhophiso).

1.3 Etsa bonnete ba hore li-sensor tsa arc li hloekile ebile ha lia thijoa ke lerōle kapa litšila.

1.4 Sheba ho tiea ha sehlopha sa hlooho pele o sebelisoa.

1.5 Hlahloba likarolo tsohle tsa ts'ebetso pele u li sebelisa bakeng sa matšoao a ho senyeha kapa ho senyeha. Likarolo leha e le life tse mengolo, tse phatlohileng, kapa tse phatlohileng li lokela ho nkeloa sebaka hang hang pele li sebelisoa hape ho qoba kotsi e mpe ea motho.

1.6 Khetha nomoro ea moriti eo u e hlokang ha u phethola kotola ea moriti (Ho sheba Tafole ea Tataiso ea Moriti). Qetellong, etsa bonnete ba hore nomoro ea moriti ke boemo bo nepahetseng ba kopo ea hau.

Hlokomela:

☆SMAW-Shielded Metal Arc Welding.

☆ TIG GTAW-Gas Tungsten Arc (GTAW)(TIG).

☆ MIG(Heavy) -MIG ka litšepe tse boima.

☆ SAM Shielded Semi-Automatic Arc Welding.

☆MIG (Leseli) -MIG ka li-alloys tse khanyang.

☆ PAC-Plasma Arc Cutting

1. Ho hloekisa le ho bolaea likokoana-hloko: Hloekisa bokaholimo ba lifilthara khafetsa; u se ke ua sebelisa litharollo tse matla tsa ho hloekisa. Kamehla boloka lisensara le lisele tsa letsatsi li hloekile u sebelisa lesela le hloekileng le se nang letlapa. U ka sebelisa joala le k'hothone ho hlakola.

2. Sebelisa sesepa se se nang lehlakore ho hloekisa khetla ea welding le hlooho ea hlooho.

3. Beha lipoleiti tsa tšireletso tse ka ntle le tse ka hare nako le nako.

4. U se ke ua qoelisa lense ka metsing kapa mokelikeli ofe kapa ofe. Le ka mohla u se ke ua sebelisa li-abrasives, solvents kapa lihloekisi tse thehiloeng oli.

5. Se ke oa tlosa filtara ea ho fifala ka boits'oaro ho helmete. Le ka mohla u se ke ua leka ho bula sefe.